- Types of Industrial Embedded Computers

- Key Features and Specifications

- Advanced Technologies in Industrial Embedded Computing

- Applications and Use Cases

- Comparative Analysis of Leading Manufacturers

- Selection Criteria and Best Practices

- Implementation and System Integration

- Future Trends in Industrial Embedded Computing

- Case Studies

- Conclusion

- Frequently Asked Questions

Industrial embedded computers are the unsung heroes of modern industrial automation and control systems. These specialized computing devices are engineered to operate reliably in harsh industrial environments, providing robust, scalable solutions for a wide range of applications. Their significance in automation, control systems, and data acquisition makes them indispensable in sectors such as manufacturing, transportation, energy, and aerospace.

Types of Industrial Embedded Computers

- Fanless Embedded Computers

- Ideal for dusty environments

- Use passive cooling techniques for enhanced reliability

- Perfect for applications where silent operation is crucial

- DIN Rail Embedded Computers

- Designed to fit seamlessly into control cabinets

- Popular in factory automation

- Offer easy installation and space-saving design

- Rack Mount Embedded Computers

- Suited for data centers and control rooms

- Offer high performance and easy serviceability

- Ideal for applications requiring multiple units in a centralized location

- Panel PCs

- Integrate display and computing capabilities

- Commonly used as Human-Machine Interfaces (HMIs)

- Available in various sizes to suit different industrial environments

- Edge Computing Nodes

- Compact, low-power systems designed for distributed computing architectures

- Ideal for IoT applications and data preprocessing at the source

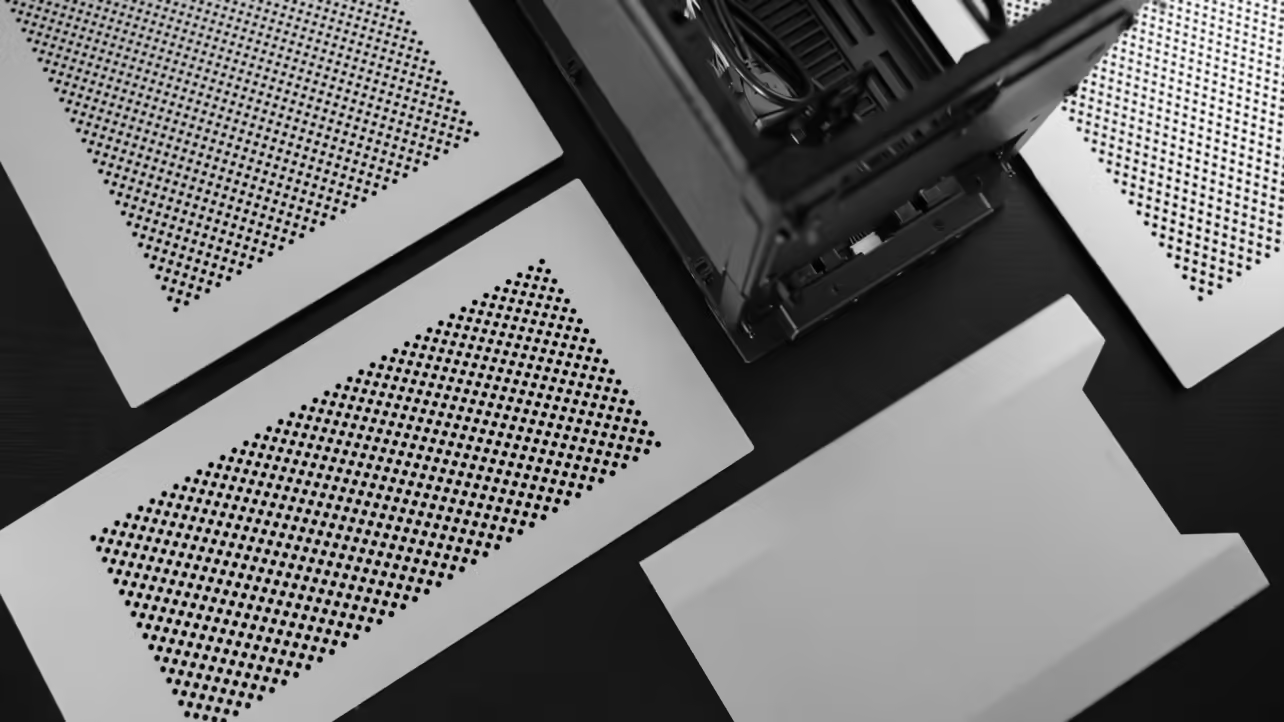

- Modular Embedded Computers

- Feature swappable I/O modules for easy customization

- Allow adaptation to changing requirements without replacing the entire unit

- Particularly useful in industries with rapidly evolving technology needs

Key Features and Specifications

When evaluating industrial embedded computers, several critical features and specifications should be considered:

- Processor: Options range from low-power ARM processors to high-performance Intel Core or AMD Ryzen Embedded series.

- Memory: Both RAM (typically DDR4) and storage (SSDs or eMMC) are crucial, with capacities varying based on application needs.

- I/O Interfaces: Industrial-grade connectors for Ethernet, serial ports, USB, and specialized interfaces like CAN or Modbus.

- Power Supply: Wide input voltage ranges (e.g., 9-36V DC) with protection against surges and reverse polarity.

- Thermal Design: Operating temperature ranges can span from -40°C to 85°C, requiring careful thermal management.

- Electromagnetic Compatibility (EMC): Compliance with standards like IEC 61000 for EMI/EMC resistance.

| Feature | Description | Typical Range |

|---|---|---|

| Processor | x86 or ARM-based | Intel Atom to Xeon, ARM Cortex-A series |

| RAM | DDR3/DDR4 | 2GB to 64GB |

| Storage | SSD/eMMC | 32GB to 2TB |

| Operating Temperature | Extended range | -40°C to 85°C |

| Power Supply | DC input | 9-36V DC |

| Ethernet | Gigabit Ethernet | 1-4 ports |

| Serial Ports | RS-232/422/485 | 2-8 ports |

| USB | USB 2.0/3.0 | 2-6 ports |

| Expansion | PCIe, Mini-PCIe | 1-3 slots |

Additional key features include:

- Expansion Options: PCIe slots, mini-PCIe, or M.2 for adding functionality

- Rugged Design: Built to withstand shock, vibration, and extreme temperatures

- Fanless Operation: For reliability in dusty environments

- Wide Input Voltage: Accommodates varying power conditions in industrial settings

- Electromagnetic Compatibility (EMC): Compliance with standards like IEC 61000 for EMI/EMC resistance

- Long-term Availability: Ensures consistent supply for industrial applications with long lifecycles

Advanced Technologies in Industrial Embedded Computing

Hardware-based Security

- Trusted Platform Modules (TPM) for secure boot and data encryption

- Helps protect against cyber threats and ensures data integrity

Real-Time Computing

- Support for real-time operating systems (RTOS)

- Time-sensitive networking (TSN) for deterministic communication

- Critical for applications requiring precise timing and low latency

Virtualization Support

- Hardware-assisted virtualization for running multiple isolated environments

- Allows consolidation of multiple functions onto a single device

AI Acceleration

- Integration of AI accelerators like Intel’s Movidius VPU or NVIDIA’s Jetson modules

- Enables local processing of complex machine learning tasks

Advanced Networking

- Support for 5G, Wi-Fi 6, and Time-Sensitive Networking (TSN)

- Ensures high-speed, reliable communication in industrial environments

Edge AI Capabilities

- Built-in edge AI for local processing of machine learning tasks

- Reduces latency and bandwidth requirements for IoT applications

Self-Diagnostic Capabilities

- Monitoring of system health, including temperature and power consumption

- Provides predictive maintenance alerts to prevent costly downtime

Applications and Use Cases

Manufacturing:

- Process control and automation

- Quality inspection systems

- Production data analytics

Transportation:

- Vehicle telemetry and diagnostics

- Traffic management systems

- In-vehicle infotainment

Energy:

- Smart grid management

- Renewable energy system control

- Oil and gas pipeline monitoring

Aerospace and Defense:

- Avionics systems

- Unmanned vehicle control

- Radar and surveillance systems

Healthcare:

- Medical imaging equipment

- Patient monitoring systems

- Pharmaceutical production control

Example: Smart Factory Implementation

In a smart factory setting, industrial embedded computers serve as the backbone of the automation system. They collect data from sensors, control robotic systems, manage quality control processes, and interface with enterprise resource planning (ERP) systems. The rugged design ensures reliable operation in dusty and vibration-prone environments, while real-time processing capabilities enable precise control of manufacturing processes.

For instance, in a mechatronic application like a multi-axis CNC machine, an industrial embedded computer might handle motion control, tool path calculation, and real-time adjustment based on sensor feedback, all while operating in a challenging industrial environment.

Comparative Analysis of Leading Manufacturers

Several manufacturers lead the market in producing industrial embedded computers. Here’s a comparison of some top players:

| Manufacturer | Key Products | Unique Selling Points | Target Industries |

|---|---|---|---|

| Advantech | Embedded Box PCs, Panel PCs | Wide product range, IoT-focused solutions | Manufacturing, Transportation |

| Beckhoff Automation | Industrial PCs, Embedded PCs | Integration with PLC and motion control | Factory Automation, Process Control |

| Kontron | COM Express Modules, Rugged Tablets | High customization, long-term availability | Aerospace, Defense |

| OnLogic | Fanless Systems, Edge Devices | Modular designs, US-based support | Industrial IoT, Energy |

| Dell EMC | Edge Gateways, Embedded Box PCs | Enterprise-grade security, global support | Smart Cities, Retail |

Some manufacturers are now offering “embedded-as-a-service” models, where the hardware is leased along with software and maintenance services. This approach can reduce upfront costs and ensure continuous updates and support, which is particularly beneficial for industries with rapidly evolving technology needs.

Selection Criteria and Best Practices

Choosing the right industrial embedded computer involves considering several factors:

- Performance Requirements: Assess the processing power, memory, and storage needs based on the application.

- Environmental Conditions: Consider operating temperature range, resistance to shock/vibration, and ingress protection (IP) rating.

- I/O and Connectivity: Ensure the system has the necessary interfaces for sensors, actuators, and network connections.

- Power Efficiency: Evaluate power consumption and heat dissipation, especially for battery-operated or confined space applications.

- Longevity and Support: Look for products with long-term availability and robust manufacturer support.

- Certifications: Check for relevant industry certifications (e.g., UL, CE, FCC) and compliance with standards.

- Total Cost of Ownership: Consider not just the initial cost, but also maintenance, support, and potential downtime costs.

Best Practices:

- Conduct thorough testing in conditions that simulate the target environment.

- Plan for future expansion by choosing systems with modular designs or upgrade paths.

- Consider the entire ecosystem, including software compatibility and integration with existing systems.

When selecting an industrial embedded computer for applications with strict timing requirements, consider systems that support IEEE 1588 Precision Time Protocol (PTP). This allows for sub-microsecond synchronization across networked devices, which is crucial for applications like distributed control systems or high-precision data acquisition.

Implementation and System Integration

- Environmental Considerations: Ensure proper enclosures and cooling solutions for harsh environments.

- Network Integration: Implement secure and reliable networking, considering factors like redundancy and segmentation.

- Software Development: Utilize appropriate development tools and frameworks for the target platform.

- Testing and Validation: Conduct thorough testing, including stress tests and EMC compliance checks.

- Documentation and Training: Maintain comprehensive system documentation and provide operator training.

Some advanced industrial embedded systems now support over-the-air (OTA) updates, allowing for remote software upgrades and patch management. This can significantly reduce maintenance costs and downtime, especially for geographically dispersed deployments.

Future Trends in Industrial Embedded Computing

- Edge AI: Increasing integration of AI acceleration hardware for local processing of machine learning models.

- 5G Integration: Embedded computers with built-in 5G capabilities for ultra-reliable, low-latency communication.

- Increased Modularity: More flexible, modular designs allowing for easy customization and upgrades.

- Enhanced Security: Implementation of hardware-based security features and zero-trust architectures.

- Energy Harvesting: Development of ultra-low-power systems capable of operating on harvested energy from the environment.

- Quantum-Resistant Cryptography: Preparation for the post-quantum era with new encryption technologies.

Research is underway on “self-organizing” industrial embedded systems that can automatically form optimal network topologies and load-balance tasks among themselves. This could lead to more resilient and efficient industrial control systems, particularly in large-scale deployments.

Case Studies

Case Study 1: Smart Grid Management

A major utility company implemented a network of industrial embedded computers to enhance their power distribution grid. The embedded systems, featuring real-time processing capabilities and ruggedized design, were installed at substations across the network. They collected data from various sensors, performed local analytics, and communicated with the central control system.

Results:

- 30% reduction in power outages due to predictive maintenance

- 15% improvement in energy distribution efficiency

- Real-time response to demand fluctuations, enabling better integration of renewable energy sources

Case Study 2: Aerospace Manufacturing

An aerospace manufacturer integrated advanced industrial embedded computers into their production line for jet engine components. The systems, equipped with high-performance processors and machine vision capabilities, were used for quality control and process optimization.

Results:

- 40% reduction in defect rates

- 25% increase in production throughput

- Improved traceability and compliance with aerospace industry standards

Conclusion

Industrial embedded computers play a crucial role in modern industrial automation and control systems. Their rugged design, advanced features, and versatility make them indispensable across various sectors. As technology continues to evolve, these systems are becoming more powerful, efficient, and intelligent, paving the way for smarter, more connected industrial environments.

By understanding the key features, selection criteria, and future trends of industrial embedded computers, organizations can make informed decisions to optimize their operations and stay competitive in an increasingly digital industrial landscape.

Frequently Asked Questions

What makes industrial embedded computers different from regular PCs?

Industrial embedded computers are designed for reliability in harsh environments, featuring rugged construction, extended temperature ranges, and specialized I/O interfaces. They often have longer product lifecycles and are optimized for 24/7 operation.

How do I choose between an x86 and an ARM-based industrial embedded computer?

The choice depends on your specific requirements. x86 systems offer high performance and compatibility with a wide range of software, while ARM-based systems typically offer lower power consumption and are suitable for edge computing applications.

What are the key considerations for implementing industrial embedded computers in hazardous environments?

For hazardous environments, consider systems with appropriate certifications (e.g., ATEX, IECEx), sealed enclosures to prevent ingress of dust or gases, and designs that minimize the risk of sparks or excessive heat.

How can industrial embedded computers enhance cybersecurity in industrial control systems?

Modern industrial embedded computers often include hardware-based security features like Trusted Platform Modules (TPM), secure boot capabilities, and encryption acceleration. They can also support advanced network security protocols and segmentation to enhance the overall security posture of industrial control systems.

What role do industrial embedded computers play in the context of Industry 4.0 and IIoT?

Industrial embedded computers serve as key enablers for Industry 4.0 and IIoT initiatives. They act as data aggregators, edge computing nodes, and control systems, facilitating the integration of physical systems with digital technologies. Their ability to perform local processing and analytics is crucial for implementing concepts like predictive maintenance and adaptive manufacturing.

No comments yet