If you’re dealing with low-voltage remote control switching systems, you’ll find that color coding your wiring is an absolute lifesaver. Here’s why:

Easy Troubleshooting: By using different colors for different wires, you can quickly identify issues and fix them without spending hours tracing circuits.

Prevents Accidents and Safety Hazards: Proper color coding minimizes the risk of shocks and short circuits by making it clear which wire does what.

Organizes the Wiring System: It helps keep your wiring neat and organized, making future upgrades or repairs much simpler.

Ensures Compatibility: A standardized color code ensures all your components work together seamlessly, even if they’re from different manufacturers.

Related: Applications of Embedded Systems in Industry

How to Color Code Your System

Step 1: Know the Standard Colors

- Red: Positive DC voltage

- Black: Negative DC voltage

- Yellow: Switched positive DC voltage

- Blue: Return path for DC voltage

- White: AC voltage

- Green: Ground or earth

- Orange: Special functions

Step 2: Plan Your Wiring Diagram

Create a clear diagram that outlines the wiring routes and functions. This roadmap is your best friend during installation and future troubleshooting.

Step 3: Label the Wires

Use labels to double-confirm wire functions. This is especially helpful if colors fade or wires get bundled together.

Step 4: Connect the Wires

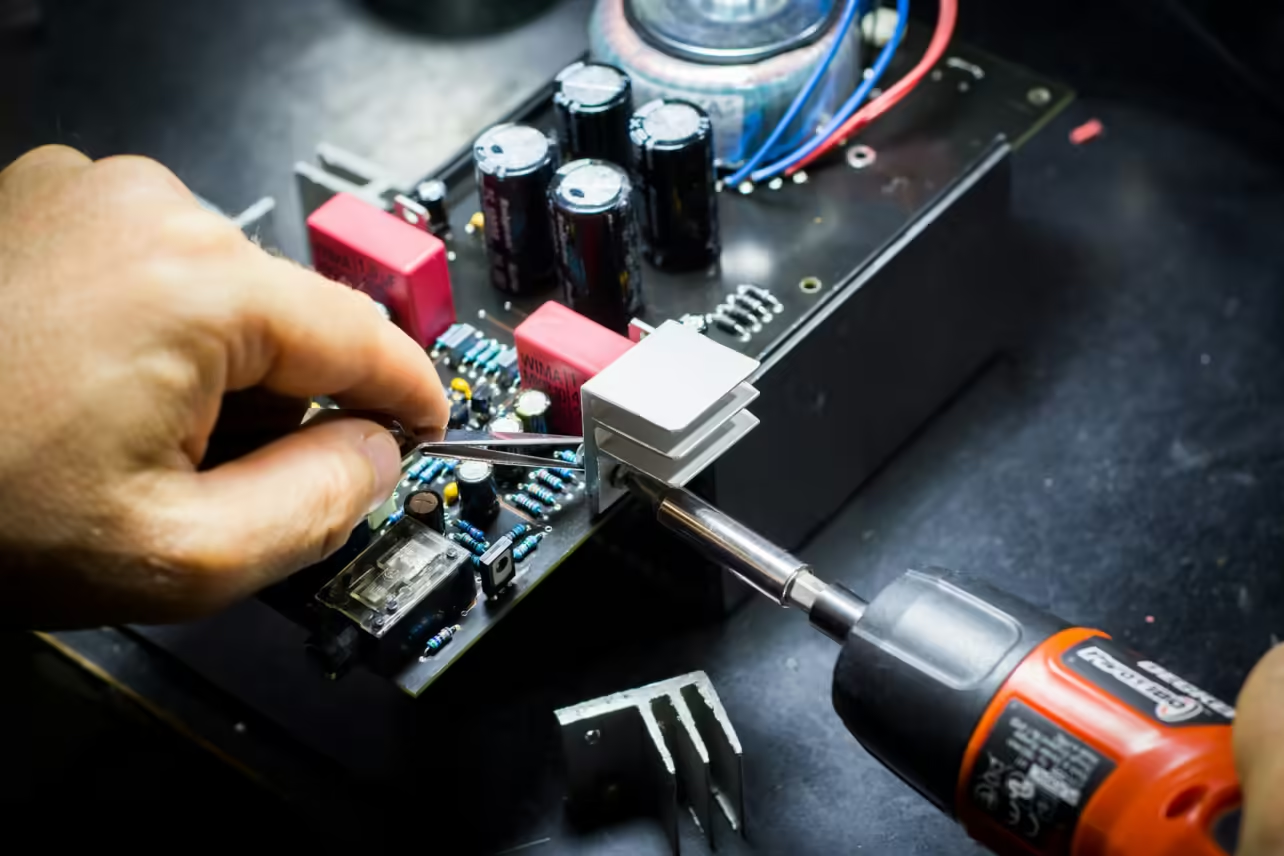

Follow your diagram and connect the wires to their terminals, matching the colors carefully. Use proper tools to secure connections.

Step 5: Test the System

After wiring, test everything with a multimeter to ensure proper voltage levels and continuity. Simulate different scenarios to check the system’s response.

Pro Tips for Effective Color Coding

- Choose vibrant, easily distinguishable colors.

- Avoid using similar shades for different functions.

- Label wires at both ends and at junctions.

- Stick to standard color codes for easier integration.

- Conduct regular inspections to catch issues early.

By following these steps and tips, you’ll make your low-voltage system safer, more reliable, and easier to manage. Happy wiring!

FAQs

Why is color coding important in low-voltage remote control switching systems?

Color coding simplifies troubleshooting, enhances safety, organizes the wiring system, and ensures compatibility among various components.

What are standard color codes for low-voltage systems?

Common codes include red for positive DC voltage, black for negative DC voltage, yellow for switched positive DC voltage, blue for return path, white for AC voltage, green for ground, and orange for special functions.

How can effective color coding prevent accidents?

It helps technicians quickly identify wire functions, reducing the risk of misconnections that could lead to short circuits or other hazards.

No comments yet