1. Definition of a Control System

A control system is a set of devices or software algorithms that manage, command, direct, or regulate the behavior of other devices or systems. Their primary goal is to maintain desired outputs despite variations in the input or external environment.

Key Points:

- Feedback: Many control systems incorporate feedback loops to compare actual output with the desired output.

- Input vs. Output: The system receives inputs (signals, data, or environmental factors) and manipulates outputs (actions, processes, or results).

- Error Correction: When discrepancies arise, the control system adjusts operations to reduce the error.

2. Key Components of a Control System

Control systems typically consist of the following core components:

- Sensors or Transducers

- Measure variables such as temperature, pressure, speed, or position.

- Convert physical quantities into signals for the controller.

- Controller

- Interprets sensor signals and decides how to respond.

- May be implemented as a microcontroller, PLC (Programmable Logic Controller), or advanced computer-based system.

- Actuator

- Executes the controller’s commands, physically adjusting the controlled process (e.g., opening a valve, changing motor speed).

- Process or Plant

- The actual mechanism or system being controlled (e.g., an engine, a production line).

- Feedback Loop

- A pathway that feeds output data back into the controller to refine and adjust future operations.

3. Types of Control Systems

Modern industries use several different classifications for control systems. The most common ones include:

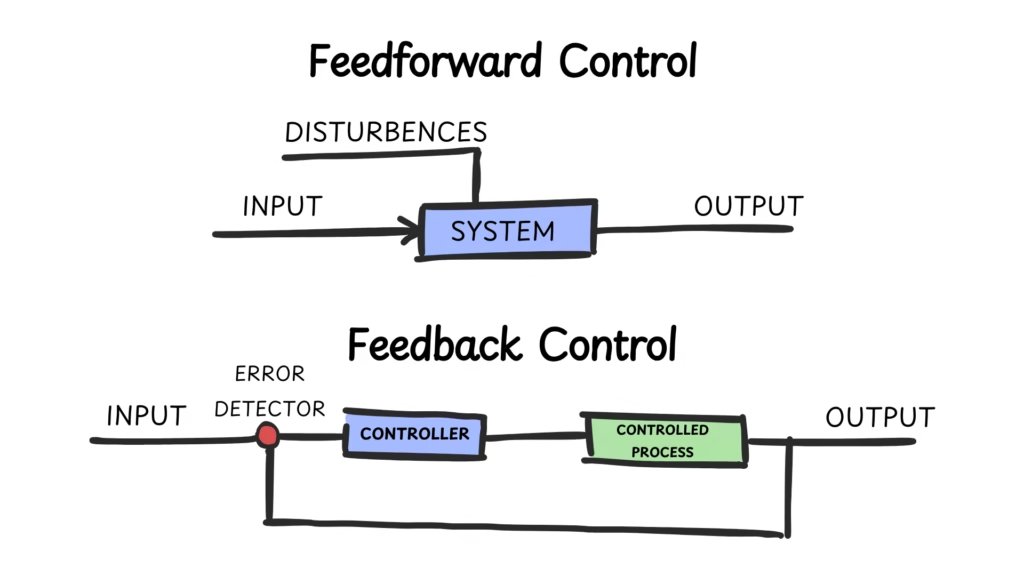

3.1 Open-Loop Control Systems

- Definition: Systems that operate without feedback; they don’t measure their output to correct any potential errors automatically.

- Example: A simple washing machine that runs for a set time regardless of load size.

3.2 Closed-Loop Control Systems

- Definition: Systems that continuously monitor and adjust their outputs based on feedback signals.

- Example: A home thermostat measuring the room temperature and switching a heating or cooling unit on or off to maintain the desired temperature.

4. Why Control Systems Are Important

Efficiency and Accuracy

Control systems reduce human error and optimize processes, ensuring consistent and precise operations.

Safety

Automated control can prevent system failures and accidents, especially in high-risk environments such as nuclear power plants or chemical processing facilities.

Cost Savings

By improving accuracy and reducing waste, control systems can significantly cut operational costs over the long term.

Scalability

From simple home automation to complex industrial networks, control systems provide flexibility and scalability as demands change or grow.

5. Typical Applications

Control systems are ubiquitous. Here are some key areas where they play a critical role:

- Manufacturing & Automation

Automated assembly lines, robotic arms, and CNC machines use control systems for high precision. - Transportation

Autopilot systems in aircraft, anti-lock braking systems (ABS) in cars, and traffic lights rely on control systems. - Energy Sector

Power grids, wind turbines, and solar farms use control systems to regulate and optimize energy generation and distribution. - Consumer Electronics

Household appliances like smart thermostats, washing machines, computer mice, and microwaves use embedded control logic for optimal operation.

6. Design Considerations and Best Practices

Developing an effective control system involves several critical steps:

- Accurate Modeling

- Use mathematical or simulation models to predict system behavior.

- Helps identify control objectives and constraints.

- Robustness

- Ensure the system can handle disturbances and uncertainties without failing.

- Over-engineer safety margins and fail-safes when necessary.

- Stability Analysis

- A stable system returns to its desired setpoint after disturbances.

- Use methods like Bode plots, Nyquist plots, or root-locus techniques to assess stability.

- Performance Tuning

- For closed-loop systems, controllers often need tuning (e.g., PID tuning) to achieve fast response without overshoot or oscillation.

- Scalability & Maintenance

- Build systems that can adapt to future expansion.

- Prioritize ease of maintenance and upgrades.

7. Conclusion

Control systems form the backbone of modern industry and daily life. Whether it’s regulating home temperatures or guiding advanced robotics on a production line, these systems ensure precision, stability, and reliability. By understanding the fundamental principles, types, and design considerations of control systems—along with their extensive real-world applications—you can better appreciate the role they play in driving efficiency and innovation.

No comments yet